Minor changes

The changes listed below are minor changes that should be implemented whenever possible on future iterations. Larger changes are listed below under Major changes , which require significant reworking of the CAD

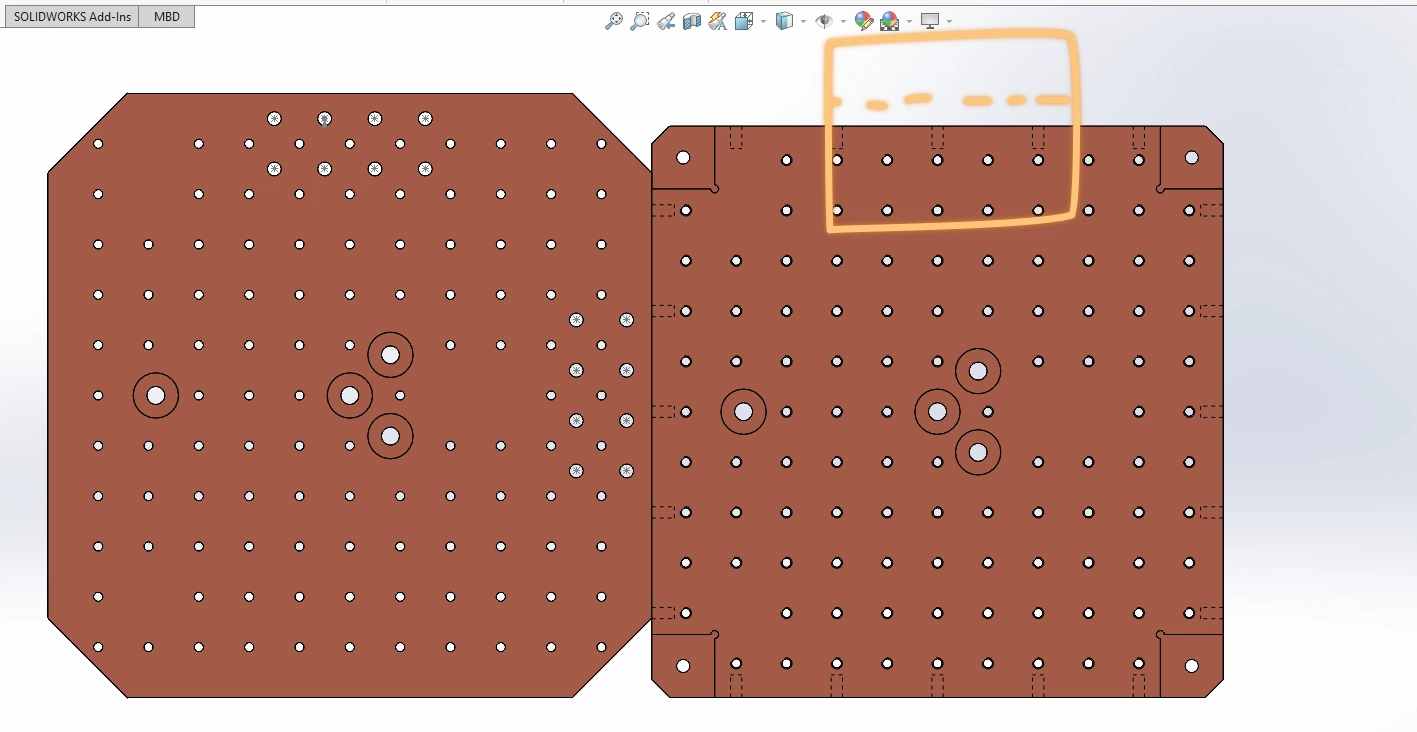

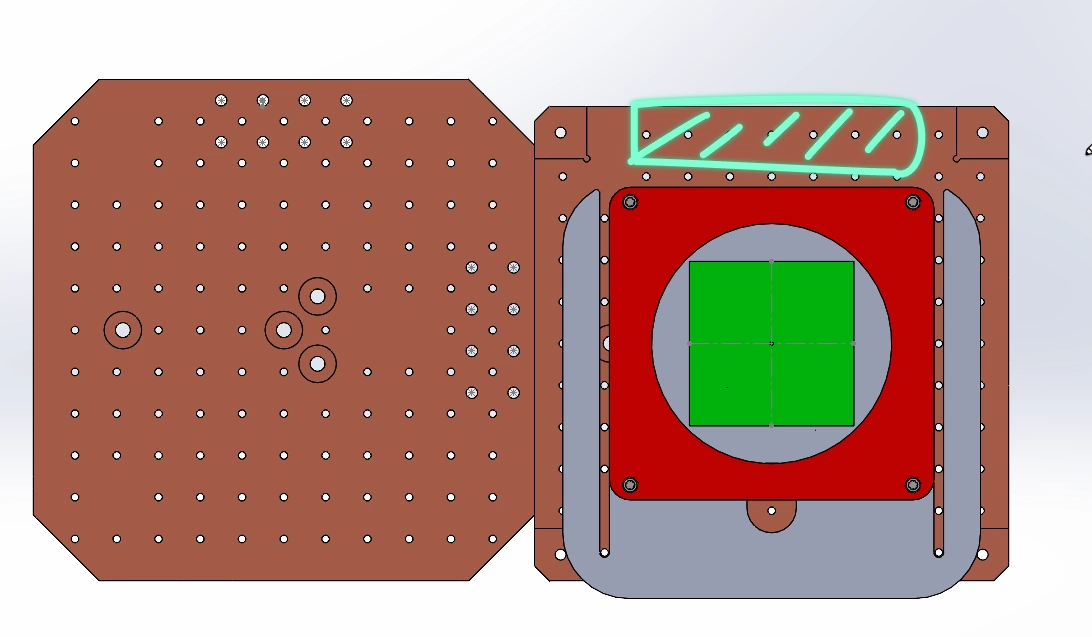

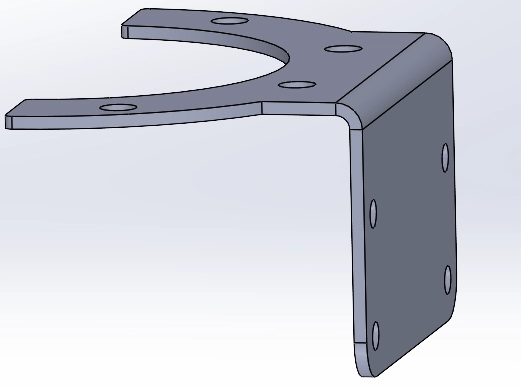

Cold head bend plates

- Right now the 4K bend plate sticks out too far and the thermal straps nearly bump into the 40K wall. Bring the 4K bend plate in a little bit so it doesn’t

- For both the 40K and the 4K bend plate, the (vertical) gap between the top bend plate and the bottom bend plate is unnecessarily large — a smaller gap would allow for shorter thermal connections

- The 40K bend plate is unnecessarily wide — since we’re not using the copper foil anymore, we can reduce the width (and place the holes better)

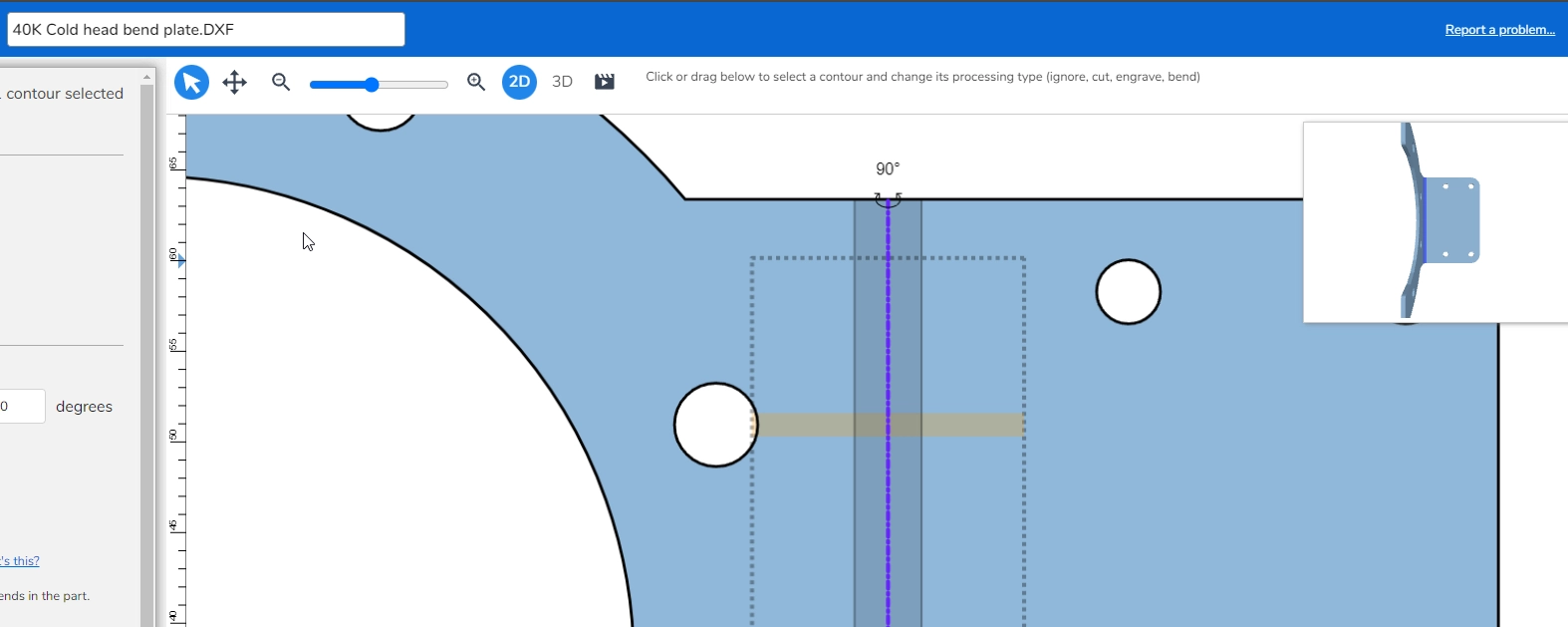

- Move bend line on 40K cold head bend plate outside of orange box

- Make 40K/4K and 1K clamping plates the same which also includes editing the clamping holes for all bend plates.

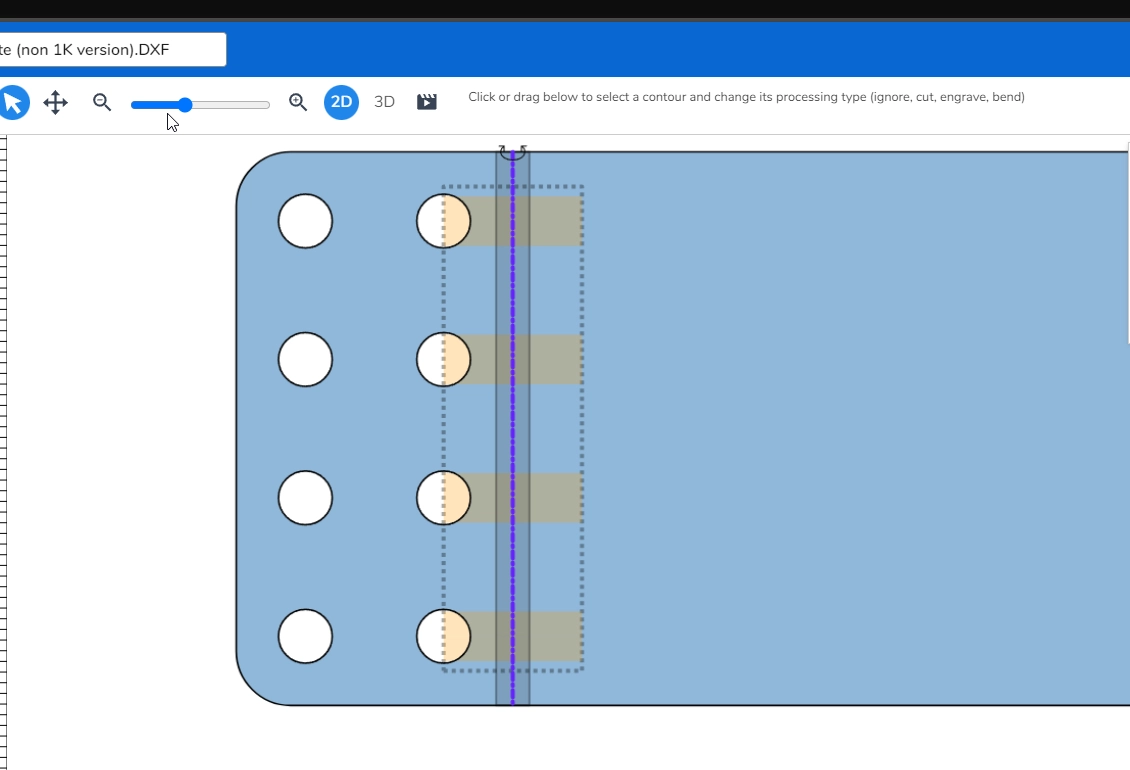

- On the 4K bend plate, remove the holes shown to the right that interfere with the bend — we just don’t need them, the holes on the left are plenty

Blackbody shield PCBs

- Offset 4K-bottom-wall door knob so it doesn’t touch the screw of the 40K-bottom-wall

- Bring in the 40K-bottom-blackbody-shield outline by 4 mm, it prevents the sides from sliding in

- Make the 40K-bottom-blackbody-shield lollipop holes ~1 mm larger so the screws don’t accidentally touch them

- Cut the bottom corners off the 40K-top-blackbody-shield, they bump into the O-ring centering ring

Miscellaneous

- Top 40K walls should have lollipop holes

Major changes

Single plate for both 4K and 1K systems

- Goal: Use a single 4K plate for either 4K system or 1K system or probe system

- Use 1K version of 4K plate and use a bend plate mounted either under the 4K plate or use only the first row of holes on top of the plate